Sejin Mechatronics

Advances Technology Innovation

Accessory

- Controller

| Code | Appearance | Acting | Type | Button mark | Emergency | Length of Cable |

| SW01 |  |

2 button | Single / Double |

English Korean Arrow |

N | Selectable |

| SW02 |  |

4 button | Single / Double |

English Korean Arrow |

N | Selectable |

| SW03 |  |

Square 2 button |

Single / Double |

English Korean Arrow |

N | Selectable |

| SW00 | Selectable | Selectable (1~10 button) |

Single / Double |

English Korean Arrow |

Selectable (Yes/No) |

Selectable |

- DC & AC Coil

| Code | COD1 | COD2 | COA1 | COA2 | COA3 | COA4 | COA5 |

| Voltage | DC12V | DV24V | AC 110V 50Hz | AC 110V 60Hz | AC 220V 50Hz | AC 220V 60Hz | AC 220V RAC |

- Mounting Bracket

| Code | Type |

| MB1 | Mounting Bracket |

- Orifice

| Code | OF1 | OF2 | OF3 | OF4 | OF5 |

| flow(I/min) | 3 | 4 | 6 | 8 | 10 |

- Solenoid valve

| Code | Appearance | Type | Max Pressure | Max Flow |

| SV1 |  |

Element for Nor Close Valve | 350bar | 25I/min |

| SV2 |  |

Element for Double Close Valve | 250bar | 22I/min |

| SV3 |  |

Element for Nor Open Valve | 280bar | 25I/min |

- Relief valve

| Code | Appearance | Type | Max Pressure |

| RV1 |  |

poppet | 210bar |

| RV2 | – | poppet | 250bar |

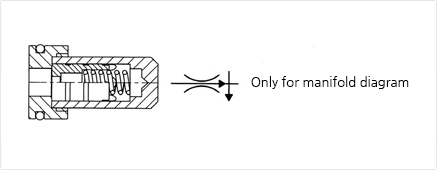

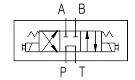

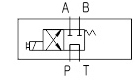

- Directional valve

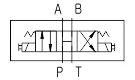

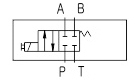

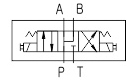

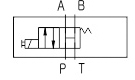

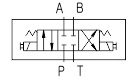

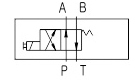

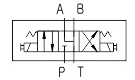

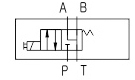

| Code | Schematic | Code | Schematic |

| DVH2 |  |

DVC1 |  |

| DVP2 |  |

DVH1 |  |

| DVC2 |  |

DVB1 |  |

| DVQ2 |  |

DVQ1 |  |

| DVU2 |  |

DVU1 |  |

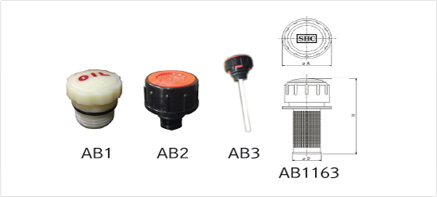

- Air Breather

| Code | Type |

| AB1 | PF 1/4, PF 3/8, PF 1/2, PF 3/4 |

| AB2 | PF 3/8, PF 1/2 |

| AB3 | PF 3/8, PF 1/2 |

| AB1163 (Unit type) |

A = 76mm / D = 48mm / H = 152mm |

| Order code ex) = AB1 + PT1/2 => AB1 – PF1/2 | |

Except for the products above, we have various products. Please Contact us. 29

Furthermore, we are not only a good manufacturer of standard(common) products, but also

a specialist of customized ones those are designed and modified by client’s special needs.

So, now we can tell you that we are ready to be of service to you.

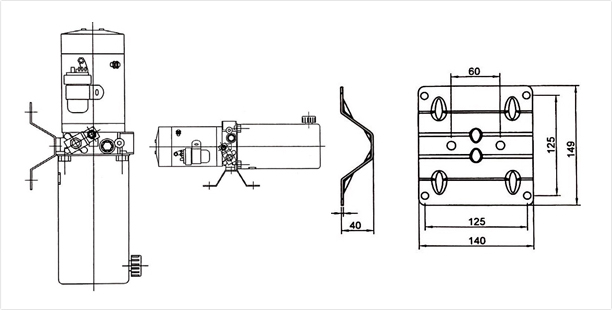

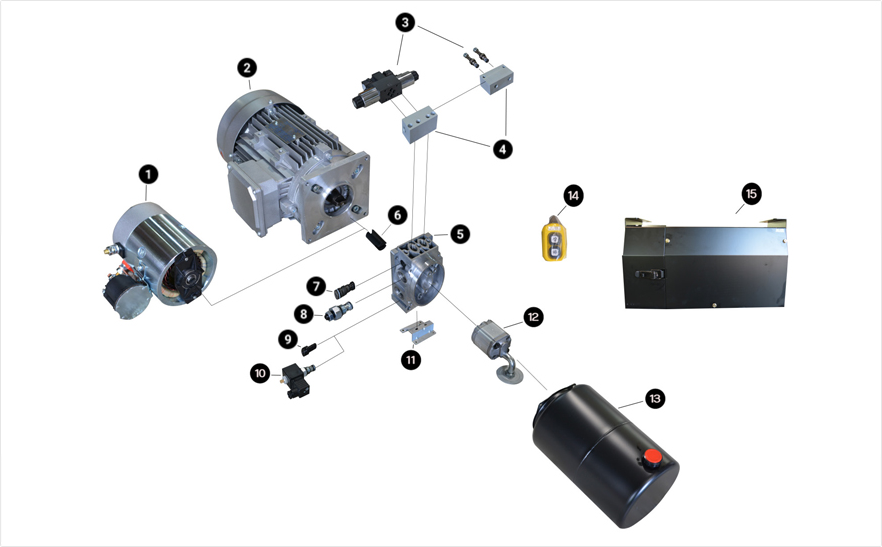

- Hydraulic composition diagram

① DC Motor ② AC Motor ③ CETOP3-Solenoid Valve ④ CETOP3-Solenoid Block ⑤ Center Block

⑥ Coupling ⑦ Check Valve ⑧ Relief Valve ⑨ Orifice ⑩ Coil&Solenoid Valve ⑪ Bracket

⑫ Pump&Suction pipe ⑬ Tank&Air Breather ⑭ Controller ⑮ BOX DC Motor

- NOTICE

> HOW TO CHOOSE THE POWER PACK&UNIT:

When selecting this hydraulic system, the motor capacity, pump capacity and tank capacity are determined by various peripheral conditions such as pressure, flow rate, operating time and operating method in the hydraulic circuit. Before making a firm order, Please do consult once with our engineer for the correct ordering code to suit your design on the system.

> OIL TANK AND TEMPERATURE:

When selecting the size of the oil tank, always select the maximum allowable working temperature within 60 degrees. Oil for Hydraulic units is a viscosity range of 15 cst. ~ 68 cst.

> WIRING AND STARTING:

Electrical wiring always select the correct wiring for the hydraulic system. When commissioning, check the rotation direction of the pump and the safety of peripheral devices.

> CLEANING AND MAINTENANCE:

The perimeter of the hydraulic system must be kept clean at all times. If a fault is found, check the safety of the peripheral device and shut off the electricity, then Please check the oil level in the oil tank, pump condition, motor condition and valve condition. The oil should be replaced after the first 100 hours of duty and again 3,000 hours or once a year.